Chatter can result in the poor machined surface, tool wear and reduced product quality. Chatter is classified into the forced vibration and the self-excited vibration in perspective of the generation mechanism. It often happens that the self-excited chatter becomes problem practically because this causes heavy vibration. Regenerative chatter due to regenerative effect is one of the self-excited chatter and generated in the most cutting operations. Therefore, it is very important to quench or avoid regenerative chatter. It is well known that chatter can be avoided by selecting the optimal cutting conditions which are determined by using the stability lobe of chatter. However, it is difficult to predict the stability lobe of chatter perfectly because the prediction accuracy of it depends on the tool geometry, the vibration characteristics of the tool system and the machine tool and the material behavior of the workpiece. In contrast, it is made clear that the stability lobe of chatter has been elevated in the wide range of spindle speed by the vibration absorber in the turning operations. In this work, the relationship between the suppression effect of the vibration absorbers and the tuning parameters of them are investigated by the stability analysis and the cutting test.

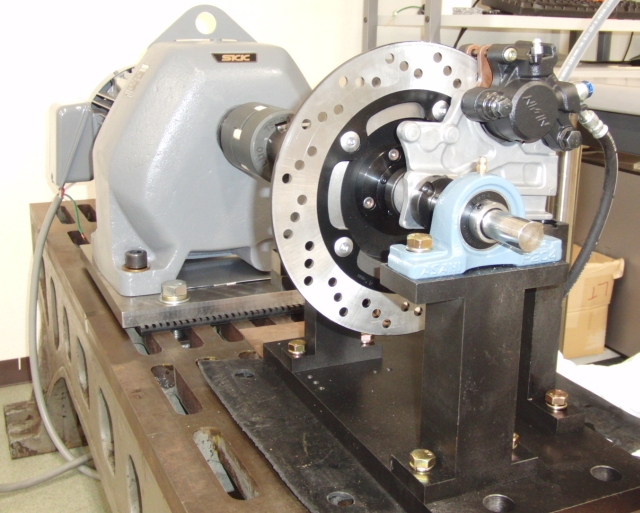

Disk brake squeal is a problem that makes drivers uncomfortable. In a luxury car, it might cause recall problem. For many years, the investigation into the generation mechanisms of squeal and the countermeasures against it have been developed. Some effective countermeasures have been developed to reduce squeal in disk brakes. However, these are empirical methods and quantitative parameters to suppress squeal have not yet been considered. In this paper, a dither control is applied to a pad to suppress disk brake squeal. It is made clear the design methods and the characteristics of a dither control to suppress the self-excited vibration caused by Coulomb friction.

In oral surgery using a rotary cutting tool, it is necessary to remove the hard layer on the surface of the bone and to finish the cutting before reaching the soft layer containing blood vessels and nerves inside. Currently, oral surgeons judge the end of cutting by sensing a subtle feel change of their hands when a cutting bur passes from the hard layer to the soft layer. However, it requires a lot of experience and skill. In this study, we aim to establish a quantitative evaluation method of the change of sense felt by the surgeon before and after reaching the soft layer.